Lets talk about joints. No, I don’t mean the joints between your bones, I’m talking about the joinery methods used in woodworking; and in this case, the drawers in your cabinetry. A good, strong joint is the cornerstone of a drawer that will last the longest and stand the test of time and durability. It’s important when you’re looking into new cabinets to take note of what kind of joints are being used, so that you know exactly what you’re getting.

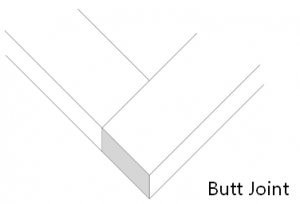

Let’s start by reviewing the most simple of joints; the butt joint. Don’t laugh! It’s a real thing, and it is essentially the kind of joint made when you join two flat pieces of wood, allowing them to rest together and securing them with glue, nails, or screws. Sometimes people modify this to make it stronger, like adding dowels, disks, or other wooden inserts, but overall it isn’t the most effective drawer joint.

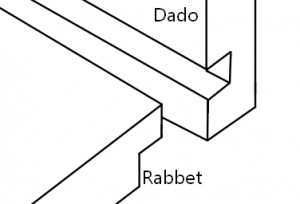

Another, more effective joinery method is that of combining a Rabbet groove with a Dado slot. A Rabbet groove is a type of cut made in the wood where one continuous notch has been formed on one side of the area that has been cut. A Dado slot, conversely, is a sort of trench-like cut made in the surface of the wood to house a notch of some sort. Dados and Rabbets go together like PB&J and are often seen used in tandem with screws, nails, or glue to create a strong and secure drawer joint.

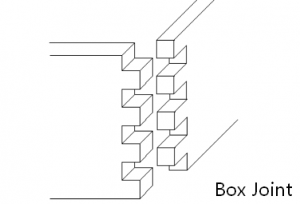

One of the stronger, better lasting joints out there is called the finger or box joint. This joint is created by cutting notches of wood all along each side of the two pieces being joined together. This locks the individual pieces of wood together, distributing the weight more evenly because there is more surface area for the wood to grab on to. This, again, can be secured by any number of methods. It’s a tough joint, but we’re not at the toughest yet.

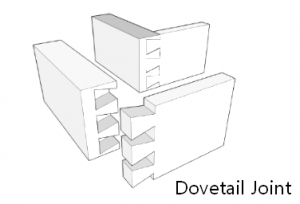

It’s time to talk about dovetail joints. Dovetail joints are a variation of box joints, where two pieces of wood have notches cut into them so that they can join together in a uniform and equalized way. However, unlike finger joints, dovetail joints are shaped to flare out at the end. This change seems small, but it plays a significant role in the strength of the drawer because the notches resist each other and stay in place, even without a method of securing them. Though it is recommended to use wood glue or some other method of security method, these joints are strong enough on their own.

These are just a few of the common types of joints used in cabinet drawers out there. Of course, there are other variations that are interesting with varying levels of strength, but when we’re talking about cabinet drawers, the most relevant thing to know is if they’re going to have butt joints, box joints, or dovetail joints. At Luxurable Kitchen & Bath, all-wood cabinetry and dovetail drawers are THE standard in 98% of our products.

Recent Comments